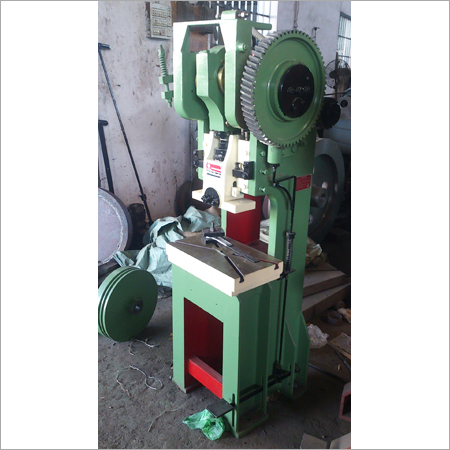

Pneumatic Power Press Machine

Price 300000.00 INR/ Piece

Pneumatic Power Press Machine Specification

- Material

- Mild Steel

- Dimension (L*W*H)

- 850 x 635 x 1450 Millimeter (mm)

- Product Type

- Pneumatic Power Press Machine

- Weight

- 900 Kilograms (kg)

- Color

- Blue & White

- Application

- Indsutrial

- Warranty

- 1 Year

Pneumatic Power Press Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 4-5 Days

- Main Domestic Market

- All India

About Pneumatic Power Press Machine

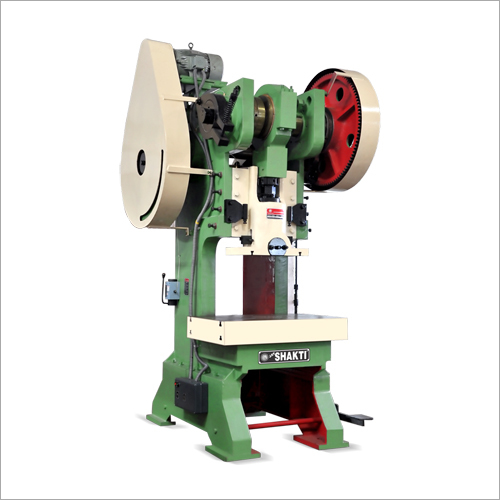

Owing to our expertise in this domain we are engaged in manufacturing exporting and supplying the premium quality Pneumatic Power Press Machine The offered machine is manufactured using high grade components and ultramodern technology under the guidance of our skilled technocrats Further the provided machine is available in different specifications and can be customized as per the key requirements of our clients within the promised time frame Due to its features such as smooth operation better performance compact design longer service and easy installation this Pneumatic Power Press Machine is highly demanded in the market

FeaturesofPneumatic Power Press Machine:

- Optimum performance

- Precision engineered

- Smooth operation

- Power efficient

STANDARD ACCESSORIES ofPneumatic Power Press Machine:

- Electric motor

- Control panel with selection of INCH ONCE AUTO mode of operation

- Foot switch fine stroke adjustment rod with limit switches

- Manual back gauge

- Standard V block And punch

- Manual lubrication

- Instruction manual

- Tilting arrangement system

OPERATIONAL ACCESSORIES

- Goose neck punch and other tooling

- Electronic stroke counter

- NC operated back gauge

- Automatic lubrication system

- Anti deflection system

Further Detail

JAYSHAKTI Presses are available in capacities of 5 Tons to 250 Tons in Double Geared or Single Geared C Type Models

- Frame Frame is of robust fabricated steel construction of rigid interlocked designIt is strainfree and supports the ram and be

- Pneumatic Clutch Brake Pneumatic clutch combined brake linked with the fly wheel engages every time when the foot switch or both hand is pressed

- Crank Shaft It is made of special EN8 high tensile steel machined and ground to highest degree of accuracy

- Bearings Bush Bearings of high grade Gunmetal machined to almost grade of accuracy with provision of oil grooves to ensure a proper fill of oil lubricant for smooth running of the machine in all conditions

- Knock Out Presses above 10 Tons capacity are fitted with knockout Brackets for stopping down the parts drawn thus facility the work

- Ram Ram is of rigid construction of high tensile cast ironcast steel with round die shanke hole and clamp It can be tightend by means of the screws on the side The slide can be adjust the stroke as desired with out hit and trial method

- Stroke Power presses are manufactured with adjustable stroke A multiple Claw Sleeve with graduation is provided to get the required adjustment in the

- Stroke Operator can adjust the stroke as desired without hit and trial method

- Fly Wheel Made of high grade CI and designed to generated the maximum energy

- Power Supply 400440 Volts 3 Phase 50 Cycles All dimensions are in mm Electricals are not under Warranty Through our technical department continual Development Variation in size and performance are subject Without prior notice

NOTE WE ALSO MANUFACTURE ANY TYPE OF PRESSES AS PER YOUR REQUIREMENT IN ANY CAPACITY

| TECHNICAL SPECIFICATION | |||||||||||

| CAPACITY | 10 | 20 | 30 | 40 | 50 | 60 | 75 | 100 | 150 | 200 | 250 |

| Crank Shaft dia | 63 | 76 | 83 | 95 | 101 | 108 | 121 | 134 | 145 | 160 | 170 |

| Stroke Adjustment | 06 to 50 | 13 to 76 | 13 to 89 | 13 to 95 | 13 to 102 | 13 to 102 | 13 to 115 | 13 to 127 | 13 to 152 | 13 to 165 | 13 to 165 |

| Max. Dist Bolster To Ram (SUAU) | 215 | 255 | 300 | 375 | 400 | 440 | 480 | 505 | 610 | 710 | 750 |

| Slide Adjustment | 25 | 38 | 38 | 38 | 45 | 45 | 45 | 51 | 51 | 51 | 63 |

| Slide face (FB x LR) | 101 x 260 | 140 x 310 | 165 x 330 | 170 x 365 | 210 x 380 | 210 x 380 | 235 x 450 | 280 x 560 | 315 x 600 | 340 x 625 | 360 x 700 |

| Punch Hole(Dia x Deep) | 25 x 45 | 32 x 50 | 38 x 65 | 45 x 76 | 51 x 85 | 51 x 85 | 55 x 95 | 63 x 102 | 63 x 110 | 63 x 110 | 63 x 110 |

| Throat distance | 127 | 152 | 178 | 203 | 260 | 280 | 292 | 318 | 369 | 420 | 450 |

| Size Of Table(FB x LR) | 254 x 430 | 305 x 508 | 355 x 558 | 405 x 660 | 520 x 750 | 560 x 787 | 585 x 863 | 635 x 1016 | 737 x 1016 | 840 x 1118 | 900 x 1150 |

| Opening in the Table Dia | 76 | 102 | 127 | 190 | 203 | 210 | 222 | 228 | 242 | 260 | 275 |

| Bolster thickness | 60 | 70 | 70 | 76 | 76 | 82 | 89 | 102 | 102 | 115 | 127 |

| Height of table surface From Floor | 720 | 750 | 750 | 775 | 775 | 800 | 850 | 825 | 850 | 850 | 850 |

| Fly Wheel Dia | 405 | 508 | 558 | 660 | 762 | 838 | 914 | 991 | 1118 | 1270 | 1320 |

| Stroke Per Minute | 70 | 45 | 40 | 35 | 35 | 45 | 45 | 45 | 35 | 32 | 30 |

| Electric Motor (H.P. / RPM) | 1/1440 | 2/1440 | 3/1440 | 5/1440 | 5/1440 | 7.5/1440 | 10/1440 | 10/1440 | 15/1440 | 20/1440 | 25/1440 |

| App. Overall Size FB x LR x HT | 850 x 635 x 1450 | 975 x 735 x 1650 | 1075 x 825 x 2050 | 1350 x 1025 x 2550 | 1450x1150 x2725 | 1550 x 1225 x 2850 | 1730 x 1400 x 3250 | 1905 x 1550 x 3525 | 2110 x 1760 x 3785 | 2385 x 2020 x 4125 | 2450 x 2100 x 4350 |

| Weight(Approx) | 900 | 1600 | 2200 | 3000 | 3500 | 4000 | 5500 | 7000 | 9000 | 11000 | 14000 |

| air pressure (kg/cm2 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Precision Engineering and Durability

Constructed from premium mild steel, this pneumatic power press machine guarantees both durability and structural rigidity. Its balanced design (850 x 635 x 1450 mm) and substantial weight (900 kg) contribute to reliable operation, minimizing vibrations during usage and improving safety and precision in industrial settings.

Versatile Industrial Applications

This machine is suitable for a wide array of manufacturing processes, including punching, forming, and cutting. Its pneumatic mechanism allows for high-speed, repetitive actions, making it a preferred choice in sectors demanding consistency and efficiency. Supplied throughout India, it supports the demands of both small and large-scale production environments.

Dependable Service and Support

As an Indian exporter, manufacturer, service provider, and supplier, we ensure comprehensive after-sales service. Customers benefit from our one-year warranty, prompt support, and guidance throughout the life cycle of the machine. Our expertise extends to installation and operational training for seamless integration into your workflow.

FAQs of Pneumatic Power Press Machine:

Q: How does the pneumatic power press machine operate?

A: The machine uses compressed air to drive its mechanical components, enabling precise and rapid pressing actions. Its pneumatic system offers smoother operation and easier control compared to manual or hydraulic presses, which enhances safety and efficiency in industrial tasks.Q: What materials is the pneumatic power press machine made of?

A: This machine is constructed from high-quality mild steel, which offers excellent strength and resistance to wear, ensuring long-term durability even in high-demand industrial environments.Q: Where can this machine be installed and used?

A: Designed for industrial usage, the pneumatic power press machine is suitable for factories, workshops, and plants involved in sheet metal processing, forming, punching, and related manufacturing operations.Q: When is the best time to perform maintenance on this machine?

A: Routine maintenance is recommended at regular intervals, as prescribed in the user manual. Checks should be performed before and after heavy usage, and scheduled servicing within the one-year warranty period helps avoid unexpected downtime.Q: What is the process for purchasing and installing the machine?

A: The purchase process involves contacting our sales team as the exporter, manufacturer, and supplier in India. Once ordered, we provide prompt delivery, installation support, and initial operational guidance to ensure proper setup and functioning.Q: How can this machine benefit your manufacturing operations?

A: The pneumatic power press machine increases production speed, delivers consistent results, and reduces manual labor. Its robust build and precision controls help enhance product quality while minimizing downtime.Q: What warranty and after-sales support are offered?

A: We offer a one-year warranty covering manufacturing defects. Additionally, our service team provides dedicated support, maintenance advice, and training to keep your operation running smoothly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Power Press Category

H Type Power Press

Price 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Size : Standard

Material : Mild Steel

Usage : Industrial

10 Ton Power Press Machine

Price 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Size : 850 x 635 x 1450

Material : Mild Steel

Usage : Industrial

Power Press Machine 10 ton

Price 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Size : 850 x 635 x 1450

Material : Mild Steel

Usage : Industrial

C-Type Heavy Duty Mechanical Power Press

Price 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Size : 635 x 560 x 1350

Material : Mild Steel

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese